Open-loop Process

Identification

|

1. Stabilize the process

either manually or automatically.

2. Set the controller to

manual mode (if the controller is still running under auto mode).

|

|

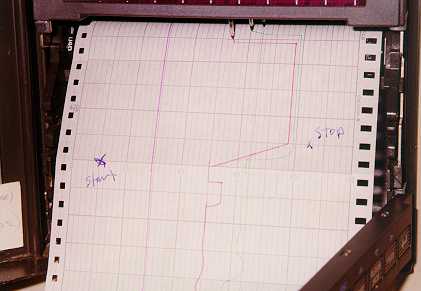

3. Record the initial value

of the controller's output.

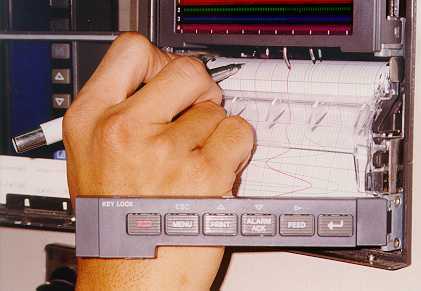

4. Mark a starting position.

A starting position must be several second a head.

|

|

5. When the recorder's pen

reaches the starting point, make a bump at the controller's output of about

5 to 20%.

6. Record the final value

of the controller's output. |

|

7. Stop the test when

ample of response curve is recorded.

8. Return the process back

to operating condition.

|

Further reading on open-loop

process identification is available at:

1. Thomas B. Kinney, Tuning

Process Controllers, Chemical Engineering, 19 Sept. 83, pp 19-20

2. Bob Connel, Process Instrumentation

Applications Manual, McGraw-Hill Book Co., 1996, pp 212-213

[Back to Main Page]