|

|

|

|

|

|

OPTIMUM

PID CALCULATION

Examples

based on Zieglar-Nichols's tuning rule

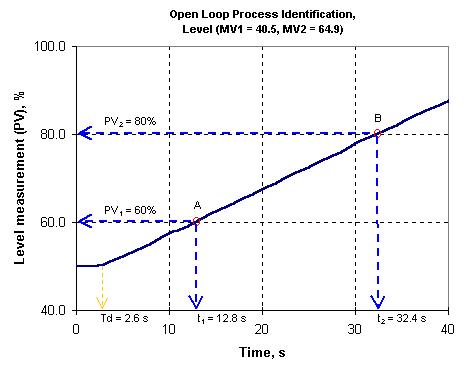

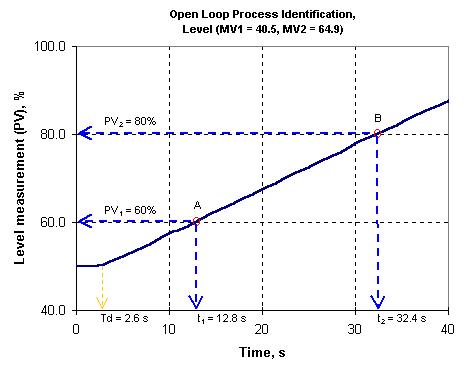

1. Example using data captured using a paperless recorder of a level increasing process

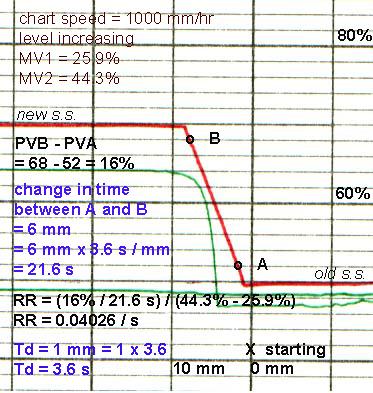

3. Example using data captured using a chart recorder of a level increasing process

1. Chart speed = 1000 mm

/ hr = 3.6 s / mm

2. x-axis (time's scale)

= 10 mm = 36 s , y-axis (measurement's scale) = 10 mm thick

mark = 10 %

3. Td = 1 mm = 3.6 s

4. Time difference between

point A and B = 6 mm = 21.6 s

5. Process rate = (68% -

52%) / 21.6 s = 0.7407 % / s

6. Controller output change

= MV2 - MV1 = 44.3% - 25.9% = 18.4%

7. RR = process rate / step

input = 0.7407 / 18.4 = 0.04026 / s

8. Level process ==> Mode

= PI

P = 111.1

x 0.04026 x 3.6 = 16.1%

I = 3.33

x 3.6 = 12 s

TEST YOUR SELF: Can you calculate the optimum PI for this level decreasing process